MEP Coordination: Explanation and Process

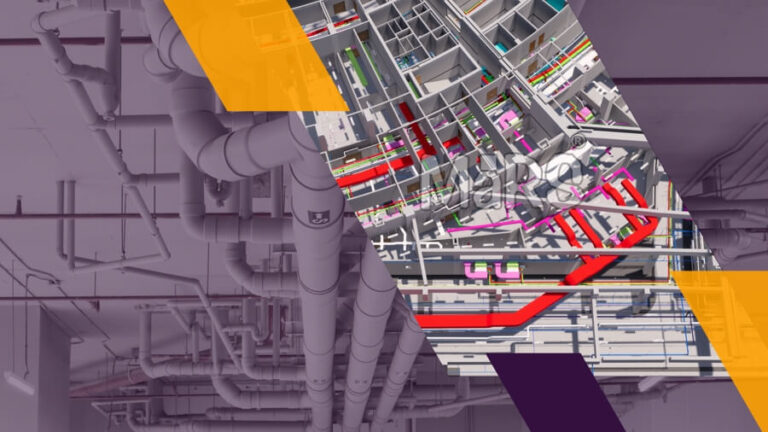

MEP coordination process is meant to be one of the most effective and efficient solutions that help deliver accurate and important information related to the BIM projects. Having said this here is a responsive guide to MEP coordination that assists in knowing and understanding what and why MEP coordination is taken into consideration and how the team of MEP engineers uses the service effectively.

The term MEP stands for mechanical, electrical, and plumbing. It is the process that involves the components that are required in the building and its structure, The use of MEP BIM Services are used for all types of construction projects be it from new houses to commercial buildings, shopping malls, universities, etc.

To make this overall process functional and effective, the component of MEP is taken into consideration in a properly coordinated manner. These BIM-coordinated models are error-free and clash-free. Also, this process helps assist major problems and results in delivering the project in time, without delay, and with any additional cost.

To understand the whole process and work, it is the AEC industries that have adopted the culture of building information modeling technology that helps get the work streamlined the entire MEP coordination process. Here are some of the stages involved in it.

Process 1: Evaluating Structural plans and Drawings

This is the very first stage of the project in which the firm and service providers are responsible for reviewing MEP drafting, MEP drawings, or the 3D models of the MEP systems that are being developed by the team of MEP contractors. Further, these plans and drawings are analyzed in detail by architectural and structural engineers so as to ensure that the entire process is having consistent and with the integration of MEP coordination specifications that are correct and reliable.

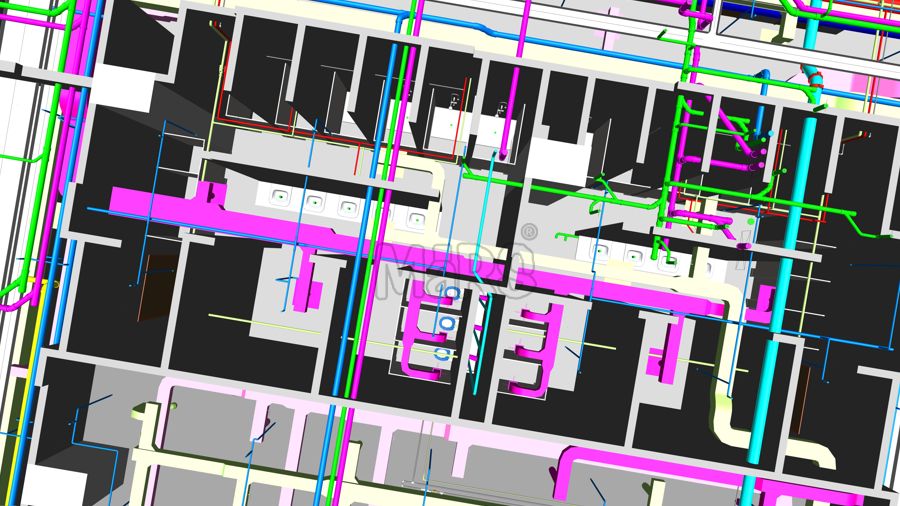

Process 2: Creating 3D Models

With the use of the consultant’s drawings and plans as checked in the first process, the next stage is to create and develop an accurate MEP model using building information modeling technology. The model of the MEP will further show all the sets of MEP that are being used within the architectural and structural limitations of the building. This level and stage of service play an important role because they lay the groundwork for several types of construction-related plans, sections, columns, elevations, etc. This process is further used to create a detailed walkthrough for the finished building.

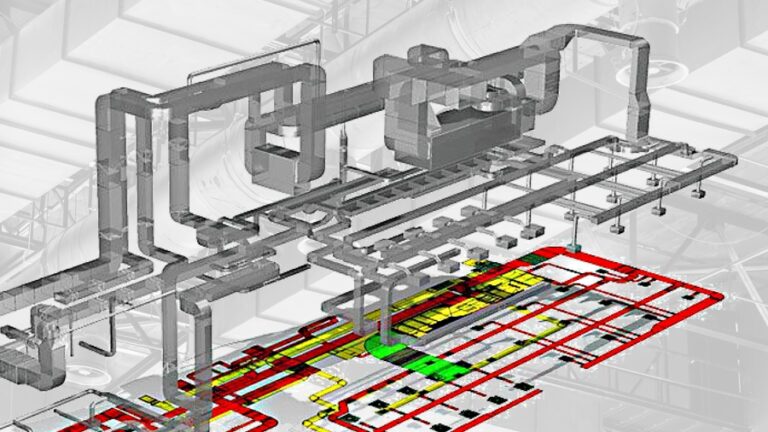

Process 3: Clash-Detection and Resolution

This is the stage in which the MEP coordination technology contractor further look in detail these 3D model and at the later stage evaluate these data and identify if there is any clashes or conflicts between the design and the elements that are architectural and structural plans, it also includes the process of MEP systems also that are planned. Any clashes, errors, or problems that are being identified will further be identified with proper solutions that are later presented to the clients for the final process.

Process 4: Producing Coordinated Drawings

Once the 3D model is created, the next process it has to undergo is the clash detection process. Once the same is done, the team goes ahead with the preparation of MEP coordination drawings so as to show the details that are being involved in the project as to how the mechanical, engineering, plumbing, and fire protection systems will work together in the same space. Moreover, to add to it the entire drawings are further be connected and have an addition to the 3D Revit modeling that ensures the exact details and measurements of the entire project.

Process 5: Creating Detailed Drawings

The next stage of MEP coordination is to create detailed drawings that will have all types of single drawings and their components. The MEP Shop Drawings are further being classified with having proper and accurate details that are required in the project. These detailed drawings include component size, height, components, and distances of the drawings that will further be taken into consideration.

Process 6: Preparing of Fabrication, Spool, and Hanger Drawings

Based on the needs and requirements of the project, the team of MEP contractors and engineers will create and develop these drawings as required and needed. Also, if required CNC machines can also be installed at the construction site to create and evaluate these drawings at the further stage.

Process 7: As-fitted Changes

The final stage of the MEP coordination process in which if there are any changes in the model and drawings are made, can be viewed and based on these changes the work at the construction site can be done on the ongoing project and can be seen with the actual construction drawings.

Read also: How To Use BIM For The MEP Installation Process?

Further, the as-fitted drawings work requires minimal changes with the use of BIM technology. This is only possible and well to do if the coordination process is well-coordinated and well-being.

For good building health, it is necessary to have a clash-free 3D MEP coordination process that is mandatory and data-driven. To evaluate all this information and get result-oriented MEP coordination it is mandatory to concentrate on the detailed design and drawings of the building structure that is a part of the business process.