How to use BIM for the MEP installation process?

We are in the information age, where data is the fuel for construction. Information that is becoming increasingly relevant and needs to be exact.

In construction, BIM (Building Information Modeling) methodology is beginning to be used as the basis for projects, but what is BIM? Many times we hear that BIM is new software, a 3D model, a database, and we could say that BIM is nothing like that, but rather a new work methodology that encompasses all of the above and puts it in order. To put it succinctly and simply, thanks to the BIM methodology we can build our virtual building.

Construction is becoming increasingly demanding to achieve efficient projects. The properties demand better buildings built in less time and cheaper. What influences that construction, architecture, and engineering companies work under pressure seeking to improve their productivity. This has led to the use of BIM, with which resources can be optimized, achieving greater performance both in the project and on-site, where it is also possible to reduce economic deviations.

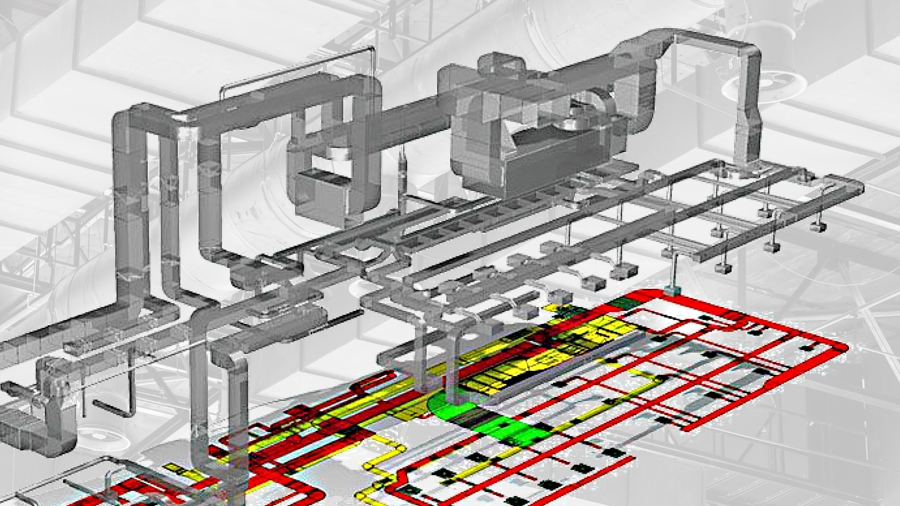

There are several BIM software on the market, in this case, we will focus on Revit, as it is the most used software in engineering. MEP BIM Modeling is part of the software for the modeling of mechanical, plumbing, and electrical installations.

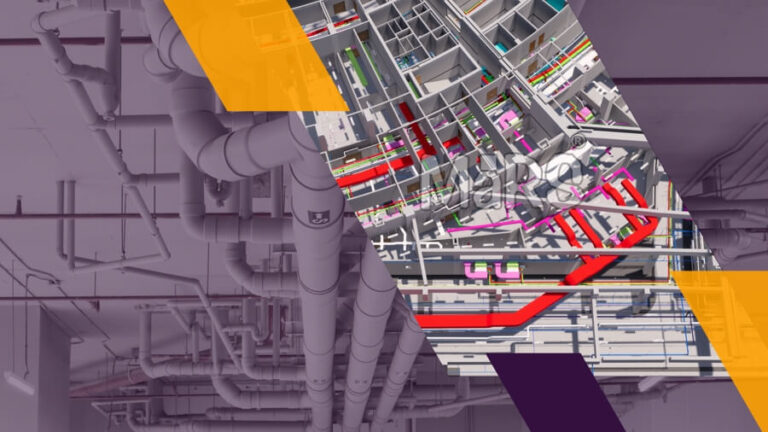

Revit MEP allows us to design all the installations taking into account the architecture and structure so that all the collisions that until now were detected on site can be avoided. This implies collaborative work between all the active agents of the project. And here we find the essence of BIM. In order to get the maximum benefit from a project, there must be collaborative work. Without it, we can have an excellent 3D Revit model with information on the objects, but once the work is done, it does not add any value.

Therefore, we verify that the basis of the BIM methodology is established in the change of the work methodology that we currently have. Once this change is assimilated, starting to work in BIM will be much easier.

At this point, it should be noted that manufacturers, who until now only had to provide a technical sheet in PDF, acquire a fundamental role in the design of these buildings. Since they must provide virtual objects, looking for the optimum point between the design and the information to be provided. In the MEP model, a pipe accessory where all its measurements and coefficient K are specified for the calculations that Revit offers. So that both engineering, installer, and the maintainer will know at all times what type of part they need and with what technical characteristics.

In this article, we are going to try to summarize how the BIM methodology helps us in the MEP processes, coordinating the architecture and structural works.

Read also: MEP Coordination: Explanation And Process

When the project reaches engineering, normally both architecture and structure have already done their work and work begins on that basis. The problem is that when the engineer has done the project, the architect usually presents changes that affect the entire MEP project, which either makes the installations redo or the interferences will have to be resolved on-site, resulting in an economic diversion and time. Revit manages to solve this dilemma, thanks to collaborative work. With the option of collaborating, we manage to work simultaneously with all disciplines, which allows us to observe changes in real-time so that any change made to the project is reflected in all the agents involved, obtaining what our virtual building should be and avoiding any diversion, both economic and temporary.

Revit MEP allows us to make a 4D BIM model in plan and automatically creates the rest of the views, elevations, sections, etc. A pumping group is observed from several views in Revit. Thanks to the parametric models, it allows us that any change made in one of the views will be automatically represented in the rest, and the engineers can work directly on the model, where the drawings themselves are the information part of our building. But we don’t focus only on the model, Revit MEP offers us the possibility of performing mechanical calculations. We can make load loss calculations, for this, it is necessary that both pipe, duct, and joints and accessories are well configured; energy calculations, with which to take out the cooling/heating load; and self-sizing calculations, in closed circuits in which it is not necessary to apply a coefficient.