Shop Drawings: The Ultimate Guide for Subcontractors

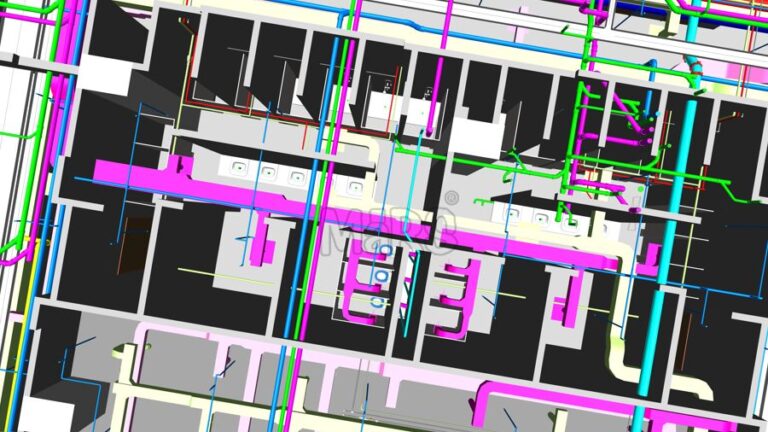

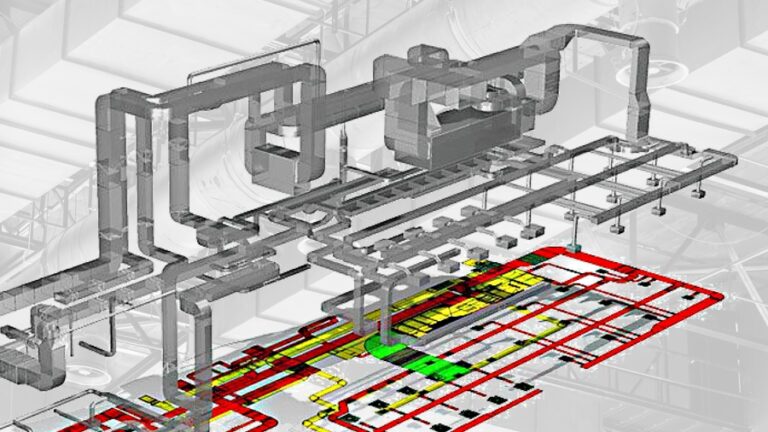

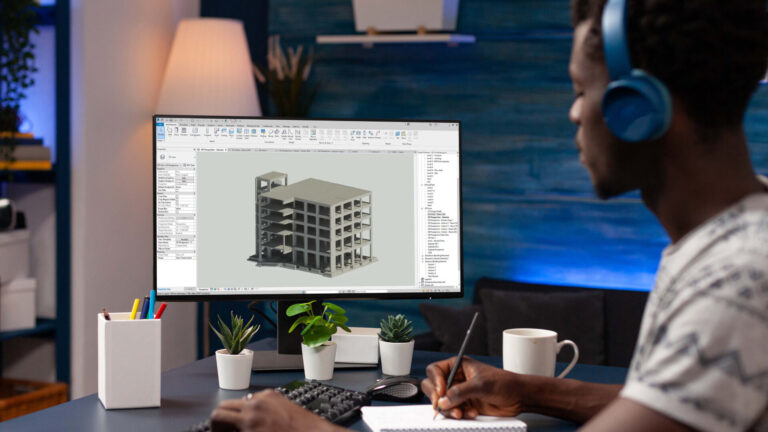

Accurate designs for building regions are created by designers using construction drawings, and BIM modeling helps these specialists understand the site and system development. Construction drawings indirectly help with details since they provide a clear picture of the construction process, including the materials needed and other requirements. They also offer a project-specific cost analysis and accurate estimate. All involved teams need building construction drawings, and shop drawings are an essential component of this set of drawings since they act as a manual for the on-site assembly and installation of prefabricated MEP components.

To guarantee that every component is manufactured, put together, and installed following industry standards, fabrication companies require shop drawings. Elevators and steel beams are two examples of modular elements included in these designs. Shop drawings are more detailed and indicate the prefabrication process than engineering and building drawings. In-depth information regarding shop drawings as a subcontractor guide, their features, when they should be generated, and the review process will all be covered in this article.

Shop Drawings and the Features that distinguish them

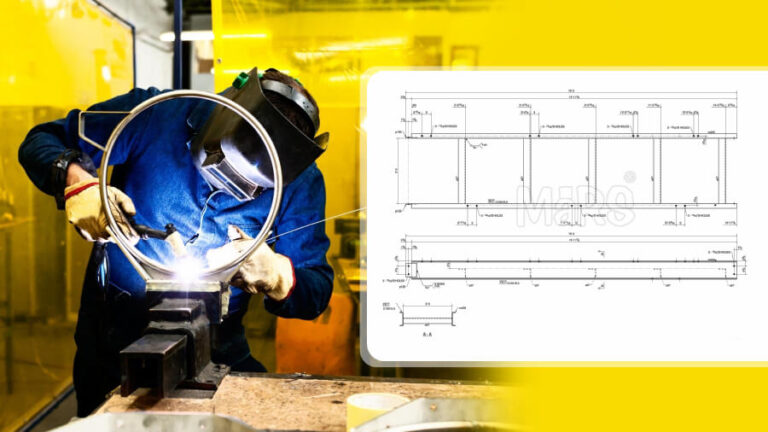

Frequently called fabrication drawings, shop drawings are comprehensive schematics produced by manufacturers, distributors, suppliers, fabricators, and subcontractors that give fabricators the data they require to fabricate, assemble, and install a building on location.

Assembly, installation, and erection instructions are included, along with dimensions and supplies. Those who create these drawings are typically engineers, steel detailers, steel modelers, and fabricators. Following are the typical features of Shop Drawings:

Data for fabrication, assembly, and installation: A MEP Shop Drawing should include all the necessary data, such as connection details, yield strength, installation orientation, codes, and standards, for the fabrication, assembly, and installation of a structure’s components.

Dimensions for on-site verifications: A shop drawing should include dimensions that indicate the sizes and locations of features. To minimize mistakes and ensure that the item will arrive at the project site suitable for installation without requiring field modification, it must be verified before manufacture.

Comparable Fabrication Information for Architects and Engineers: Architects and engineers can assess requirements and construction drawings with greater depth thanks to shop drawings derived from architectural BIM modeling. They take into account appearance, usefulness, and specific characteristics and are clear and detailed.

Preparation of Shop Drawings

For building projects, shop drawings are essential for creating precise designs before work starts. These designs need to be submitted by contractors before their initial payment request. It is ensured that the design, installed components, and specific characteristics of the building are familiar by creating shop drawings early in the planning process. This guarantees that throughout the building process, designers, manufacturers, contractors, and project managers are all in agreement. The process of creating shop drawings starts once registered designers, specialists, and project consultants have reviewed the drawings and requirements.

Review Process of Shop Drawings

To ensure effective delivery of fabricated materials and compliance with design intent and fabrication standards, shop drawing reviews are essential to quality management in the construction industry. Listed below is the process:

Submission and review schedule: A contractor needs to set up a submission and review plan for shop drawings, giving enough time for them to be reviewed and then submitted again.

Assigning responsibility: If the contractor gives a fabricator’s engineer the task of reviewing and sealing a set of drawings, they ought to specify which drawings the engineer is expected to evaluate and seal.

Subcontractor’s Review: After receiving all Shop Drawings, the registered professional shall examine and review the drawing to make sure the design as stipulated in the construction specifications is correctly represented and implemented.

Confirmation of Review: Shop drawings should be examined for overall compliance with the design concept. Any deviations observed from the design intent should be noted and informed by the reviewer.

Revisions and Changes coordination: A contractor must address the site conditions and component installation in the shop drawings and resubmit them if instructed to do so.

What is the Need for Shop Drawings?

In the building industry, shop drawings are essential to a seamless construction process because:

- They enable engineers to evaluate the accuracy of fabricators, structural engineers to verify that concrete reinforcement maintains property integrity, and manufacturers to comprehend materials and specifications.

- They support cost analysis, schedule optimization, handover facilitation, and BIM 3D modeling.

- Roles and tasks are clarified, coordination is improved, risks are decreased, and engineering precision is increased.

Conclusion

Shop drawings are essential for effective communication between owners, designers, contractors, subcontractors, and suppliers, as may be inferred from the study above. Contractors must deal with extended lead times and strict timelines while defining final design elements. While BIM 3D modeling improves the quality of architectural work, advanced detailing software saves money and time.